Rims chromium-plated steel or raw

A range of rims "special collection" .

For over 30 years, we have been developing a wide range of rims in raw steel or chrome plated. Over the years, this range has gradually expanded. Today, we are able to offer a complete range of specific models, for vintage vehicles from the 1930s to 1980s, for motos, mopeds and certain cars equipped with « tringle » rim.

You're sure to find the right size or model for your vehicle, at diameter, profile or in terms of finish. Our "rims chromium-plated steel " section is made up of standard models, which are fairly common, as well as some very limited series. The diameters (in inches) range from 10 to 26 inches and include more common sizes such as 17, 18 and 19 inches, fitting most vehicles from the 30s to the 80s.

The chrome plating website, France, uses criteria adapted to the collection, enabling us to guarantee quality results, both aesthetically and technically.

" Our profile types ... "

Profile FS

Profile GP

Profile US

Profile V38

Profile WM

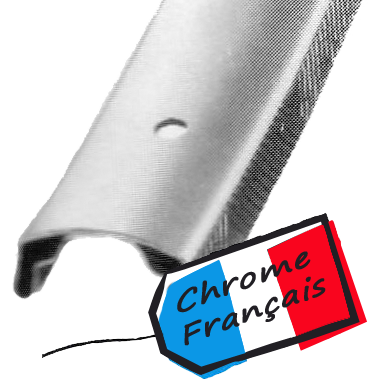

Chrome plating French

Trivalent chrome

Guaranteed 20 micron

What is chrome plating?

"The chrome plating operation consists of covering a steel part with a greater or lesser thickness of chrome."

We have chrome plated decoration applied to all our chrome plated finished parts. The purpose of chrome plating "décor" is to give parts the shiny appearance characteristic of polished chrome plated surfaces.

The "manual" dipping technique enables us to master the finish required and adapted to the criteria of the collection world. This process produces a high-gloss, resistant finish with a thickness of 20 micron.

chrome plated is not stainless steel, in order to preserve the quality and durability of your parts, it is necessary to store your vehicles in a ventilated and dry place, free from humidity

"About rims chrome plated es.."

Our rim range is entrusted to a local, French company with solid expertise in surface treatment, capable of delivering work of excellence.

The chrome plating rims range is produced using a technique known as "manual soaking ", a meticulous process carried out in several stages to obtain a perfect, controlled, top-quality finish of chrome plating, perfectly suited to the requirements of the collection.

For your information, the chrome plated used meets current environmental standards, notably through effluent treatment and the use of trivalent chrome plated III (less polluting for the environment than hexavalent chrome).

We still have a long way to go to reduce our environmental impact, particularly in terms of surface treatment. That's why we've chosen to work with a company that is committed to taking action, and has already introduced processes that are less polluting and more respectful of our planet. For the time being, there is no substitute for chrome, which is why offering a high-quality finish (albeit more expensive) gives a profound meaning to our approach. We give priority to durability and quality through this range chrome plated and try to make our humble contribution

" Also discover raw steel, aluminium and black-painted wheels..."

To complement the chrome plating rim range, we offer models in raw steel, rims aluminum (on command) and some sizes of rims painted in black Epoxy finish for models of vehicles from the 20s and 30s.